Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Power outages stop businesses from working in the U.S. every year. You need a commercial generator to keep your business safe from these problems. The U.S. Energy Information Administration says outages can last over eight hours each year. These outages can cost businesses up to $27 billion. To make sure you have good backup power, check these important things before you install:

Power capacity

Generator type and fuel source

Installation process

Commercial site location

Compliance and regulations

Routine maintenance

Cost and support

Getting a commercial generator helps lower downtime and keeps emergency systems working. Picking the right commercial generator gives you good value and steady backup power.

Find out how much power your building needs. Make a list of all equipment. Add extra power for sudden surges. Add more for future growth.

Pick the best generator type for your site. Choose fuel that is easy to get. Think about what your business needs. This helps save money. It also helps things run well.

Plan how you will install the generator. Get the site ready first. Put the generator close to the main panel. Use an automatic transfer switch for safety.

Follow local laws and rules. Get all the permits you need. This keeps your setup legal and safe.

Take care of your generator often. Check it every day. Have a professional look at it once a year. This makes sure it works when you need it.

You must know how much power your building needs before picking a commercial generator. Make a list of every machine and system that needs backup power. Write down the starting and running wattages for each one. You can find these numbers in manuals, on equipment labels, or from the company that made them. If you do not know the exact numbers, use common power charts to guess.

Tip: Change all power numbers to kilowatts (kW) so you can compare them easily.

Here is an easy way to figure out your total power needs:

1. Write down all equipment and their running wattages.

2. Find the item with the biggest starting wattage.

3. Add this highest starting wattage to the total running watts.

4. Change the total to kilowatts (kW).

5. Add 25% more to cover power surges and future needs.

You can also use a clamp-on ammeter to check your building's highest power use. Look at your utility bills to see the biggest demand in the last year. Add extra power to make sure your commercial generator can handle everything.

A table can help you keep track of your numbers:

Equipment | Running Watts | Starting Watts |

|---|---|---|

Lighting | 2,000 | 2,000 |

HVAC System | 5,000 | 8,000 |

Computers | 1,500 | 1,500 |

Refrigeration | 3,000 | 5,000 |

Security System | 500 | 500 |

When planning for growth, only add extra power if you know you will expand soon and know the exact needs. If you are not sure, wait until you expand. Measure the new power needs then. This helps you avoid buying a commercial generator that is too big, which wastes money and fuel.

Some companies use more than one commercial generator together. This lets you add more units as your power needs go up. It keeps your system working well and saves money. Always make sure your commercial generator size follows the National Electrical Code (NEC) and matches your building's single-phase or three-phase power needs.

Note: If your commercial generator is too small, it can shut down or break your equipment. If it is too big, you waste energy, spend more money, and make more pollution. Try to have your commercial generator run at 70-80% load for the best results.

When you pick a commercial generator, you should know the main types. Each type is good for different places and needs. There are three main types of commercial generators. These are standby generators, portable generators, and inverter generators.

Standby generators stay in one spot. They turn on by themselves when the power goes out. You see these in hospitals and factories. They give steady power and last many years.

Portable generators are easy to move. You use them for short jobs or outdoor events. They do not run as long or as quietly as standby generators.

Inverter generators make clean power for sensitive electronics. They run quietly and save fuel by changing how much power they make.

You need to choose the right fuel for your commercial generator. The most common fuels are diesel, natural gas, and propane. Each fuel has good and bad points.

Fuel Type | Advantages | Disadvantages |

|---|---|---|

Diesel | Works well under heavy loads, lasts long | Loud, makes more pollution, needs upkeep |

Natural Gas | Burns clean, quiet, steady supply from pipelines | Not as strong, supply can stop in disasters |

Propane | Burns clean, stores well, lasts long | Less power, needs bigger tanks, less common |

Diesel generators are good for long jobs and heavy use. Natural gas generators are quiet and make less pollution. Propane generators burn clean and store well, but need more fuel and bigger tanks.

LIYU Group sells gas generators and containerized gas generator sets. These use natural gas and propane. They fit commercial needs, run quietly, and work well where you need clean power and easy setup.

You should check if you can get fuel easily before buying a generator. If your site has a natural gas pipeline, you can use a natural gas generator. If not, diesel or propane may be better. Propane is good for faraway places where fuel is hard to find. Diesel works well where there are no gas lines and you need long run times.

Tip: Always plan for safe fuel storage. Follow local rules for tanks and safety.

Some generators use two fuels. You can switch between diesel and natural gas if one runs out. This helps you keep power during emergencies. You also need to think about space for tanks and how easy it is to get fuel delivered.

Pick a generator that matches your site, fuel supply, and business needs. This helps you get steady power and save money.

Planning is important before you install a commercial generator. You must follow each step to keep your generator safe and working well. The steps include checking the site, building the base, wiring, and putting in the transfer switch. Doing each step helps you avoid problems. It also keeps your business running when the power goes out.

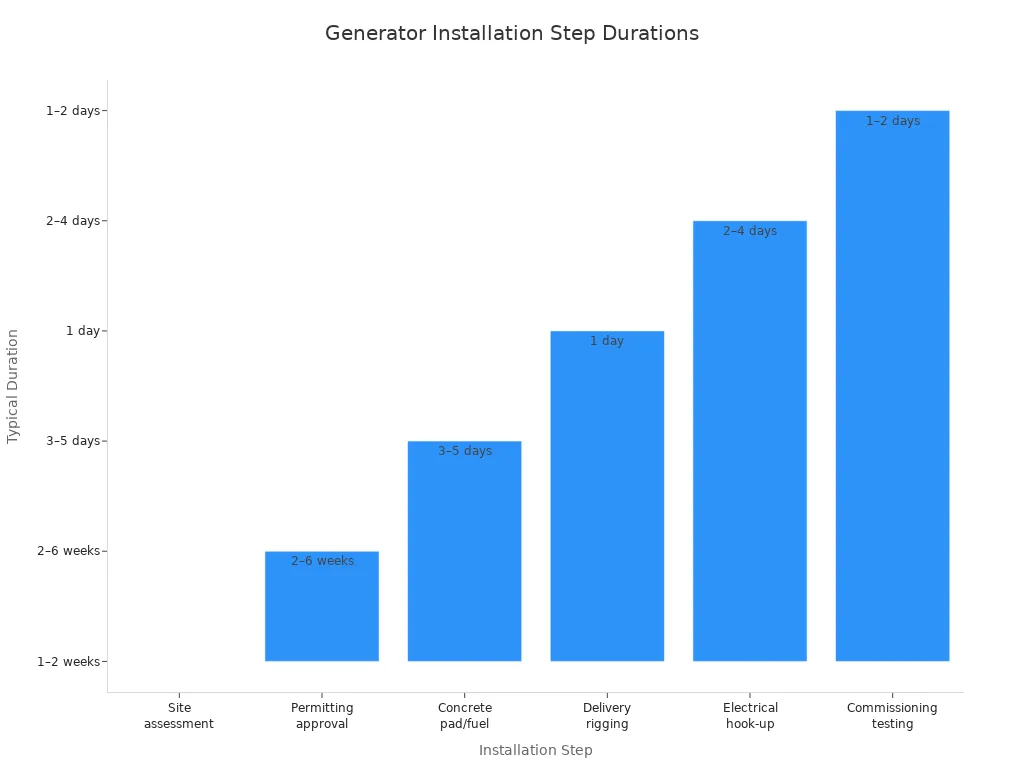

Step | Key Task Description | Typical Duration |

|---|---|---|

1 | Site assessment and load calculation | 1–2 weeks |

2 | Permitting and utility approval | 2–6 weeks |

3 | Concrete pad and fuel infrastructure | 3–5 days |

4 | Delivery and rigging | 1 day |

5 | Electrical and gas hook-up | 2–4 days |

6 | Commissioning, testing, and training | 1–2 days |

You need to plan the site before installing the generator. Pick a spot close to the main panel. Make sure it is not in a flood zone. The spot should be easy to reach for repairs. Clear the ground and build a strong concrete pad. The pad should be flat and bigger than the generator base. Raise the pad so water does not collect. Put steel bars inside the pad to make it stronger. Leave space around the generator for air and service. Put up a fence and lights to keep the area safe.

Tip: Trucks can deliver the generator more easily if the site is easy to reach. Repairs are also faster.

Put the generator near the main electrical panel. This helps you save money on wires. It also makes the installation safer. Short wires mean less power loss and fewer risks. Leave two or three feet of space around the generator. This helps with air flow and repairs. Do not put the generator near doors, windows, or air vents. This lowers the chance of carbon monoxide. It also makes fixing the generator easier.

The automatic transfer switch (ATS) is very important. It knows when the power goes out and starts the generator. The ATS switches your building from grid power to generator power fast. When the grid comes back, it switches again and turns off the generator. The ATS stops power from going back into the grid. This keeps workers and equipment safe. It also keeps your power steady and your systems working.

Note: Many places require the ATS by law for commercial generator installation.

A good plan for installing a generator covers everything. You need to think about where to put it, how to install it, and how to keep it safe. Each step helps you avoid trouble and keeps your backup power ready.

Picking the best spot for your commercial generator is important. It helps keep people safe. It also lowers noise and protects the generator. You need to check local laws and weather. Make sure you can reach the generator for repairs. Planning ahead stops problems and keeps your business working.

You have to choose if the generator goes inside or outside. Both choices have good and bad sides. Look at the table to see the differences:

Factor | Indoor Generator | Outdoor Generator |

|---|---|---|

Building Codes & Permits | Needs special rooms, ventilation, exhaust | Must follow zoning, noise, and permit rules |

Climate & Environment | Protected from weather | Needs weatherproof enclosure |

Noise | Noise stays inside, easier to control | Must use sound enclosures |

Space Availability | Needs large indoor space | Easier if space outside is open |

Installation Complexity | More complex, higher cost | Simpler, lower cost |

Security | More secure inside | Needs fencing, cameras, lighting |

Maintenance Access | Easier access, protected from weather | Must plan for weather and security |

Think about weather problems like floods or strong winds. Check how close the generator is to your electrical room. If you put it inside, make sure there is enough space. You also need good air flow. Old buildings might need costly changes.

Generators can be loud. You should know how much noise yours makes. Local rules say how loud it can be. Most commercial generators make 65 to 100 decibels. Many cities only allow 52–62 decibels in homes. The table shows how loud different generators are:

Generator Size (kW) | Noise Level (dB(A)) | Noise Comparison | Noise Mitigation Methods |

|---|---|---|---|

50 kW | ~85 | City traffic | Sound enclosures, mufflers |

1500 kW | ~105 | Jet airplane | Advanced silencers, enclosures |

You can make the generator quieter with sound covers or mufflers. Put it far from neighbors if you can. Always check city rules before picking a spot. Think about wind, rain, and heat too. Outdoor generators need covers that keep out bad weather.

Tip: Put the generator where it will not bother anyone.

You need to keep your generator safe from thieves and damage. There are many ways to protect it:

Bolt the generator to a concrete pad.

Build a strong fence around it.

Set up cameras and alarms.

Use steel covers for the generator and fuel tank.

Add bright lights and warning signs.

Hire guards if needed.

Put GPS trackers on expensive generators.

Keep the area bright and hard to get into. Write down the serial number and mark it on the generator. Use sensors to protect fuel tanks. Good security keeps your generator safe and ready to work.

You need permits before you put in a commercial generator. These permits keep your business safe and legal. Most cities want you to get different permits. You may need:

Site plan approval

Electrical permits

Structural permits

Mechanical permits for fuel lines

Planning or zoning approvals

You must show where the generator will go. The site plan should show how far it is from property lines, vents, and doors. If your generator is heavy, you might need special engineering for the concrete pad. The planning department often asks for a development plan. You must give them the manufacturer's installation manual to check.

Inspections happen at different times. Inspectors look at your site before, during, and after installation. They check if you follow the codes, wire everything right, and connect fuel safely. You must pass all inspections before you use the generator. If you skip a permit or fail an inspection, you might get fines or have to wait longer.

Tip: Work with licensed electricians and contractors who know local codes. They help you follow all rules and avoid trouble.

Commercial generators must follow strict emissions and safety codes. These rules protect people and the environment. The Environmental Protection Agency (EPA) sets rules for clean air. Your generator must meet these rules. Some states make you use ultra-low sulfur diesel or special fuels. You may need exhaust systems to lower pollution.

States limit how long you can run a generator for non-emergencies. Most let you run it up to 100 hours each year. In emergencies, you can run it as long as you need. You must do regular engine maintenance to follow the rules.

Safety codes cover many things:

Code/Standard | What It Covers |

|---|---|

National Electrical Code (NEC) | Electrical wiring and grounding |

NFPA 110 | Emergency and standby power systems |

Local Fire Codes | Fuel storage and fire prevention |

Building Codes | Placement, ventilation, and structure |

You must install the generator the way the manufacturer says. Good ventilation and space help stop carbon monoxide from building up. You also need to keep records of maintenance and inspections. Local officials may ask to see these records during checks.

Remember: Following all codes and permits helps you feel safe. It keeps your business ready for any power outage.

You must take care of your generator to stop power loss. Checking it often helps you find problems early. A simple schedule makes sure your generator works when needed.

Daily: Look for leaks or damage. Check oil, coolant, and fuel. Watch gauges and warning lights. Make sure the battery is charged.

Weekly: Start the generator with no load. Clean or change air filters. Look at belts and hoses for damage.

Monthly: Run the generator with a load. Change oil and filters if needed. Drain water from fuel tanks. Test emergency switches and alarms.

Quarterly/Annually: Have a professional check it. Do a load bank test. Flush the cooling system. Check all wires and breakers.

You also need to check the radiator and coolant. Look at hoses and belts for cracks. Test the battery and clean the ends. Drain old fuel and clean the lines. Check exhaust pipes for leaks. Test the control panel and safety shutdowns. These steps help stop breakdowns and keep your generator ready.

Maintenance Frequency | Key Tasks and Components Covered |

|---|---|

General Inspections (Each Use) | Test battery, look for leaks, check intake/exhaust, remove debris |

Weekly | Check fluids, run generator, check exhaust, look at control panel |

Monthly | Load test, keep fluids full, check radiator, clean corrosion |

Annual | Change oil, replace filters, flush cooling system, check electrical system |

Tip: Write down all maintenance. This helps you track problems and follow safety rules.

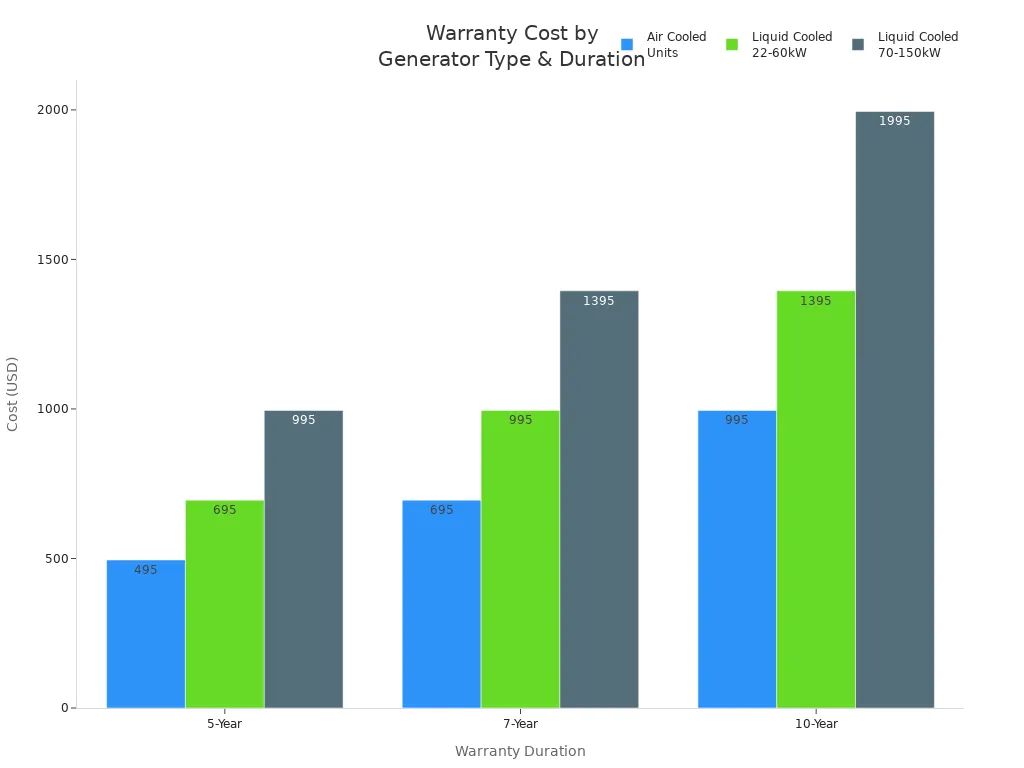

You should know what your warranty covers before buying. Warranties last five to ten years. The price depends on the generator's type and size. Air-cooled units cost less to cover than liquid-cooled ones. Some brands give longer coverage if you buy soon after purchase.

Warranty Duration | Generator Type | Cost Range (USD) | Conditions/Notes |

|---|---|---|---|

5-Year | Air Cooled Units | $495 | Valid for 2014+ models, <12 months from purchase |

7-Year | Air Cooled Units | $695 | Valid for 2014+ models, <12 months from purchase |

10-Year | Air Cooled Units | $995 | Valid for 2014+ models, <12 months from purchase |

5-Year | Liquid Cooled Units (22-60kW) | $695 | Nexus & Evolution models, <12 months from purchase |

7-Year | Liquid Cooled Units (22-60kW) | $995 | Nexus & Evolution models, <12 months from purchase |

10-Year | Liquid Cooled Units (22-60kW) | $1,395 | Nexus & Evolution models, <12 months from purchase |

5-Year | Liquid Cooled Units (70-150kW) | $995 | Nexus & Evolution models, <12 months from purchase |

7-Year | Liquid Cooled Units (70-150kW) | $1,395 | Nexus & Evolution models, <12 months from purchase |

10-Year | Liquid Cooled Units (70-150kW) | $1,995 | Nexus & Evolution models, <12 months from purchase |

Support is important too. Many companies give 24/7 help, quick repairs, and expert advice. Ask about these services before you buy. Good support keeps your generator working and helps you worry less.

You need to think about all the costs before buying a commercial generator. The price is not just for the generator. You also pay for putting it in, getting permits, and setting up fuel. Look at the table below to see what you might pay:

Cost Component | Estimated Cost Range |

|---|---|

Generator Purchase | $15,000 – $50,000 |

Installation Fees | $3,000 – $20,000+ |

Permits and Inspections | $500 – $2,000+ |

Fuel Source Connection | $2,500 – $10,000+ |

Maintenance and Repairs | $500 – $5,000+ annually |

The price of a commercial generator changes based on size, type, and where you put it. Small generators can be $5,000 to $15,000. Big ones can cost $50,000 or even more. If you need extra wires or work, installation costs go up. Permits and checks add more money to the total. Fuel setup prices change depending on what kind you use and how you store it. Do not forget about these first costs.

You have to take care of your generator so it does not break down. Each year, you might spend $150 to $600 for regular care. This pays for oil changes, new filters, and system checks. Some brands ask for $200 to $400 each year for service. If something breaks, repairs can cost $100 to $800. Portable units usually cost less to keep up. Engine generators need more work and cost more to fix.

Tip: Getting your generator checked often saves money later. It helps stop big problems and keeps your power on.

You should save money for upgrades or new generators as your business gets bigger. Old generators break more and may not follow new rules. If you cannot find parts, it is better to buy a new one. Use the table below to help you plan:

Factor | Repair or Replace? | Budget Tip |

|---|---|---|

Generator Age | Replace if very old | Set funds aside for new units |

Damage Level | Repair minor, replace major | Adjust budget for big repairs or new buys |

Parts Availability | Replace if parts scarce | Plan for higher costs if parts rare |

Downtime Impact | Replace if frequent stops | Budget for lost work time |

Efficiency/Compliance | Replace for new standards | Save for upgrades to meet new laws |

Do not forget to plan for things you will need later. Think about all the costs, like upgrades and times when the power is off. This helps you be ready and keeps your business working.

Before putting in a commercial generator, look at your power needs. Think about the generator type and what fuel it uses. Check the steps for installation and where you will put it. Make sure you follow rules and keep up with maintenance. Think about how much everything will cost. Work with experts who know about permits and safety codes. They also help with regular service.

You get setups that are safe and follow the rules.

You stop losing money from power outages.

You have backup power when there is an emergency.

Plan ahead so your business does well for a long time. Pick solutions you can trust. LIYU Group has gas generators to help your business stay open. Contact LIYU Group if you want more information.

First, write down all your equipment. Find the running and starting wattages for each one. Use a table to keep track of these numbers. Add 25% more for future growth. If you need help, ask an electrician.

Equipment | Running Watts | Starting Watts |

|---|---|---|

HVAC | 5,000 | 8,000 |

Lighting | 2,000 | 2,000 |

Check your generator every day for leaks and battery power. Test it once a week to make sure it works. Change the oil and filters every month. Get a professional to inspect it every year. Regular service helps your generator work in emergencies.

Daily: Look at fluids and battery

Weekly: Run a test

Monthly: Change oil and filters

Yearly: Get a full inspection

You must get permits for electrical, fuel, and site work. Local rules tell you which permits you need. You have to pass inspections before using your generator. Ask your city office for more information.

Tip: Licensed contractors can help you get permits.

You can put your generator inside if you have good ventilation. You also need to follow safety codes. It needs a special room and an exhaust system. Most businesses put generators outside because it is easier and safer.

Location | Needs Ventilation | Needs Exhaust | Common Use |

|---|---|---|---|

Indoor | Yes | Yes | Less common |

Outdoor | No | Yes | More common |

Diesel is strong and works well for big jobs. Natural gas is clean and quiet. Propane stores well and lasts a long time. Pick the fuel that fits your site, supply, and business needs.

Diesel: Strong and reliable

Natural Gas: Clean and quiet

Propane: Stores long and clean